1

1~2Stage

1~2Stage

2

3~4Stage

3~4Stage

3

5~6Stage

5~6Stage

4

7~8Stage

7~8Stage

5

9~10Stage

9~10Stage

6

11~12Stage

11~12Stage

7

13~14Stage

13~14Stage

1

1~2Stage

1~2Stage

Step1: PRE-BENDING

Edge Bending and Press Bending that is applied for the products with thickness greater than 40T Performed before the processing

Step2: PRESS-BENDING

Carry out bending in the shape of J, C, O, using 7000 ton press2

3~4Stage

3~4Stage

Step3: POST-BENDING

Edge Bending and Press Bending that is applied for the products with thickness less than, and equal to 40T Performed before the processing

Step4: TACK WELDING

Tack welding process for regular welding after the completion of forming (Bending)3

5~6Stage

5~6Stage

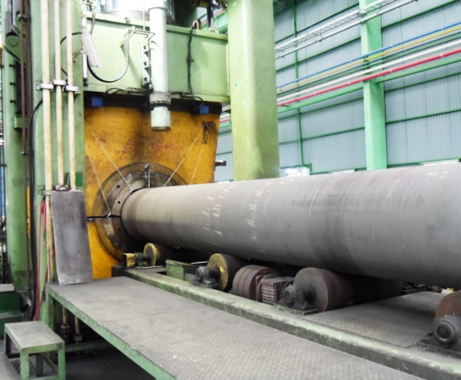

Step5: EXTERNAL WELDING

Exterior welding process of PAW and/or GTAW after the completion of tack welding

Step6: LONGITUDINAL SEAM MILING

In case of edge forming Y-model, groove manufacturing process for exterior welding4

7~8Stage

7~8Stage

Step7: INTERNAL WELDING

GTAW internal welding process after the completion of external welding

Step8: RADIOGRAPHIC TEST

Automatic controlled RT system for checking the welding zone integrity5

9~10Stage

9~10Stage

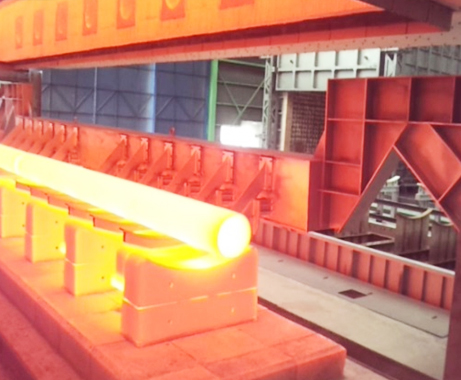

Step9: HEAT TREATMENT

Batch type heat treatment process for solution treatment of STS pipe

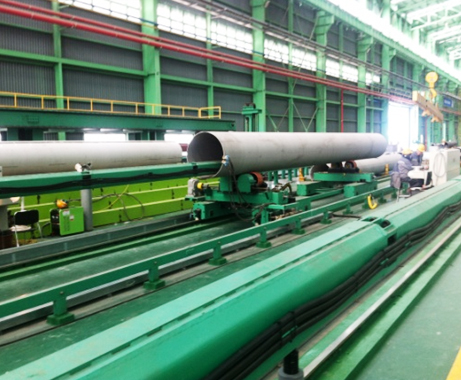

Step10: SIZING

Sizing operation to guarantee the roundness and straightness of the product size6

11~12Stage

11~12Stage

Step11: END FACING

Process of bevel manufacturing both tips of tubes according to the product standard for field connection welding

Step12: PICKING

Cleaning the product surface and passivation treatment process using acid solution7

13~14Stage

13~14Stage

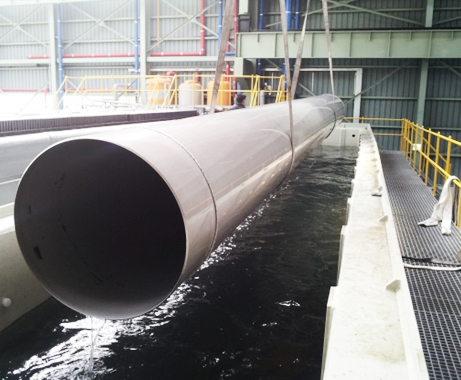

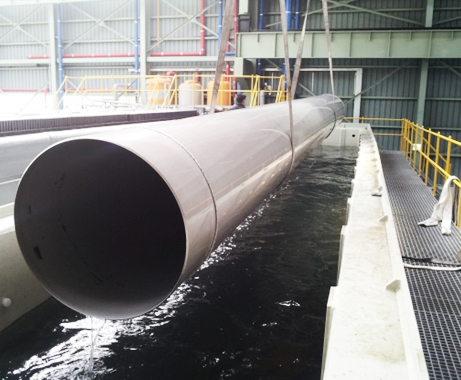

Step13: HYDROSTATIC TEST

Test processing of water pressure for line pipe and steel pipes used in plumbing