STEP 1: UNCOILING

Process to supply skelp to forming process by uncoiling the wound skelp

STEP2: LEVELING

Process to flatten the uncoiled skelp

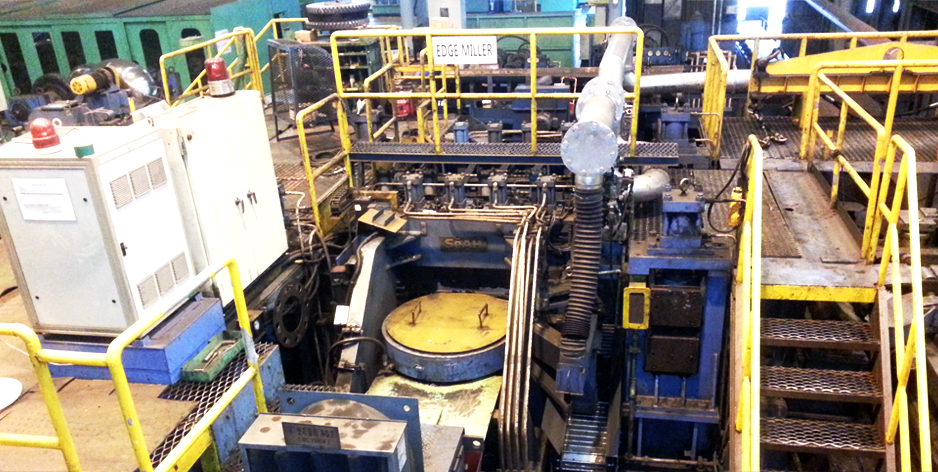

STEP3: EDGE MILLING

Process that secures the weldability of ERW by milling both longitudinal edges of skelp with square-shape(I type)

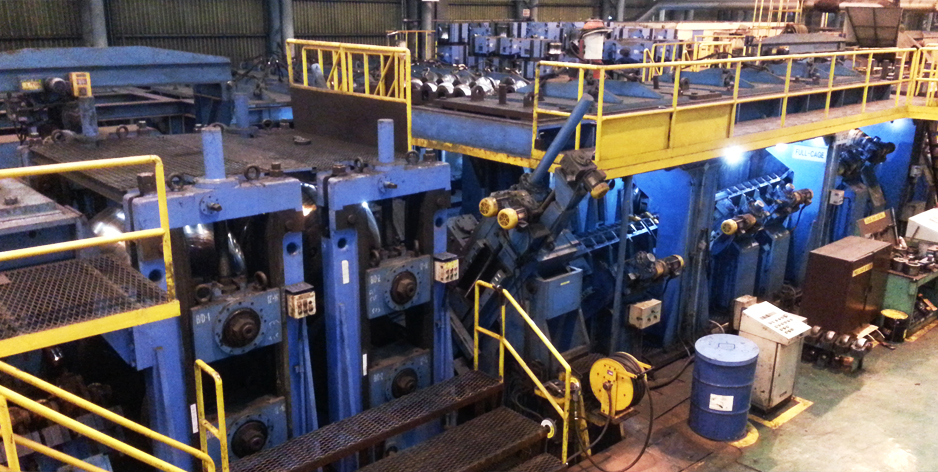

STEP4: FORMING

Process to transform a flat skelp into a round pipe and to prepare edge alignment for welding

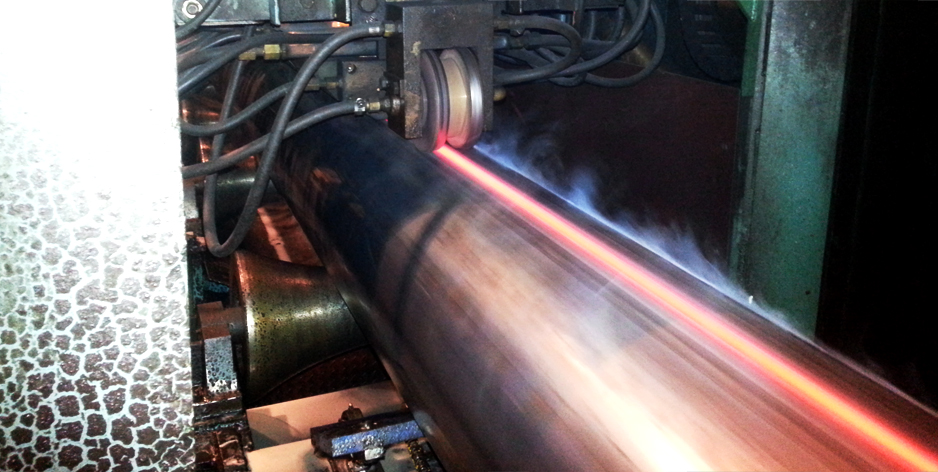

STEP5: WELDING

The edges of the skelp are heated by high frequency welding and are squeezed together by pressure.

STEP6: HEAT TREATMENT

Process to heat-treat welds of pipe by using inductors (Normalizing)

STEP7: COOLING

Process to cool the normalized welds by air and water

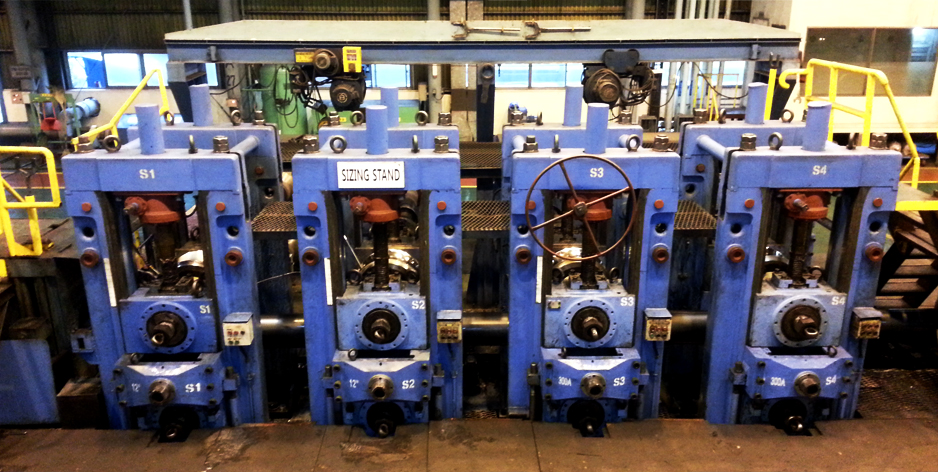

STEP8: SIZING

Process to calibrate pipe dimension as per customers’ requirements

STEP9: CUTTING-OFF

Process to cut the pipe length as per customers’ requirements

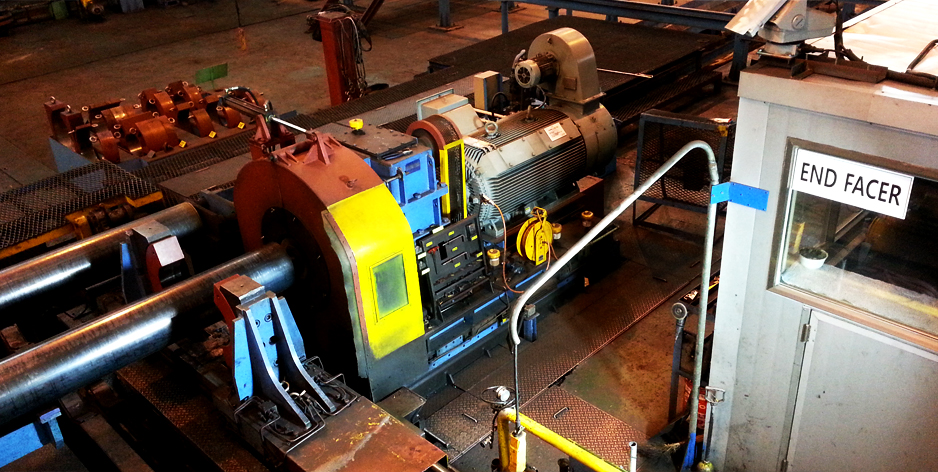

STEP10: END FACING

Process to machine both pipe ends as per customers’ requirements.

STEP11: HYDROSTATIC TEST

Process to test pipe hydrostatically with constant pressure and holding time.

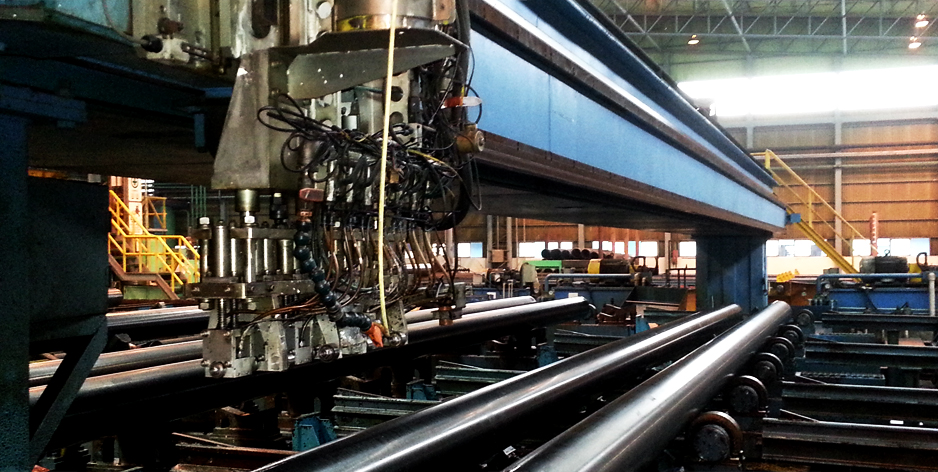

STEP12: ULTRASONIC TEST(SEAM & FULL BODY)

Process to inspect welds and base metal of pipe by using ultrasonic waves

STEP13: MILL COATING

Process that prevents corrosion by spreading inhibited oil on product surface

STEP14: DIMENSION / VISUAL INSPECTION / PACKING

Process that packages and decides the acceptance/refusal by confirming the size of the final product and exterior condition